The Hidden Reality Behind Many Vendors Outsourcing to Unknown Third Parties

When customers place orders, they expect a seamless experience that reflects the brand's values and promises. However, the truth behind many vendors outsourcing to unknown third parties can shatter these expectations, leading to detrimental consequences:

1. Inconsistent Logos

One common repercussion of third-party outsourcing is the use of inconsistent logos on products or packaging, creating confusion among consumers and diluting brand identity. This issue often arises in the realm of branded merchandise, which is frequently produced without proper oversight.

2. Late Deliveries

Third-party vendors may struggle with meeting deadlines, resulting in delayed deliveries that disappoint customers and harm brand reputation.

3. Lack of Accountability

Outsourcing to third parties can lead to a lack of accountability, making it challenging for businesses to address issues promptly and ensure customer satisfaction.

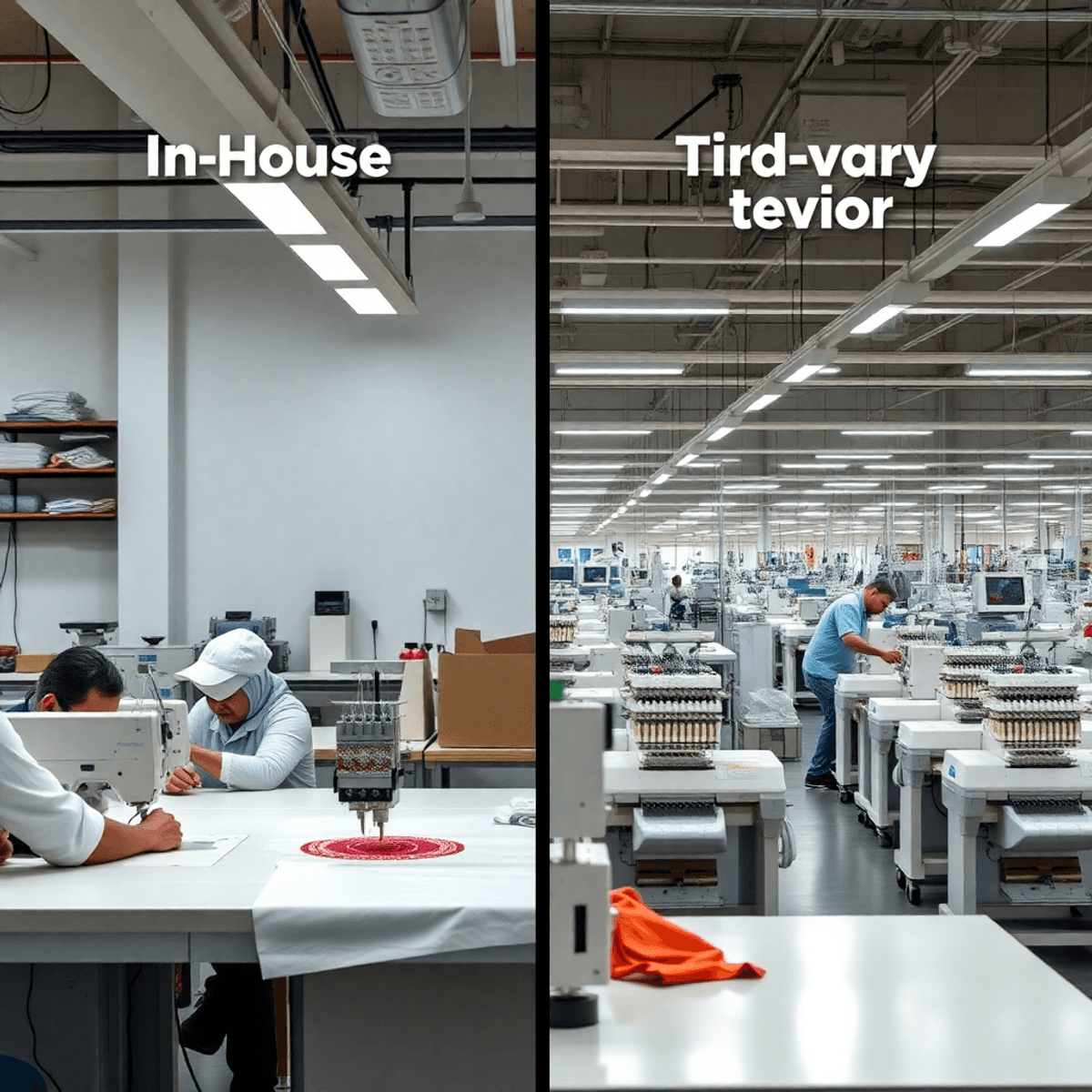

Understanding the critical disparity between third-party outsourcing and in-house production is crucial for safeguarding brand reputation and enhancing customer satisfaction. By delving into the intricacies of vendor accountability, quality control measures, and order fulfillment processes, businesses can make informed decisions that prioritize consistency, reliability, and customer trust.

For instance, companies could consider producing their branded merchandise in-house to maintain control over quality and branding. This could involve exploring options like custom trucker hats or embroidered polo shirts which have proven effective as marketing tools when personalized correctly. Additionally, understanding different printing methods such as screen printing vs heat press transfers can further enhance the quality of branded merchandise.

Understanding Third-Party Vendors: Benefits and Risks

Third-party vendors are external companies or service providers contracted by businesses to handle specific tasks, products, or functions that the primary company may not perform internally. Outsourcing these operations allows organizations to leverage external expertise and resources without expanding their in-house capabilities.

Benefits of Third-Party Vendors

- Cost Savings: Outsourcing often reduces expenses related to labor, equipment, and infrastructure by shifting certain operational responsibilities to specialized vendors.

- Access to Specialized Expertise: Third-party vendors typically possess niche skills and technologies that businesses may lack internally, enhancing service quality or product innovation. For instance, a company might hire a third-party vendor specializing in branded signage which can act as a silent salesperson for their business.

- Scalability: Vendors can quickly scale services up or down based on demand fluctuations, offering flexibility without the overhead of managing additional permanent staff.

- Operational Efficiency: Delegating non-core activities enables businesses to focus on strategic priorities while benefiting from vendors’ streamlined processes and economies of scale.

Risks Associated with Third-Party Vendors

- Security Breaches: Sharing sensitive data with external parties increases vulnerability to cyberattacks, data leaks, or unauthorized access.

- Compliance Failures: Vendors may not fully adhere to industry regulations or standards, exposing the contracting business to legal and financial penalties.

- Operational Disruptions: Dependency on third parties introduces risks such as delayed deliveries, inconsistent quality, or failure to meet service level agreements (SLAs).

- Vendor Risk Management Required: Implementing rigorous vendor risk management (TPRM) practices—including due diligence, contract clarity, ongoing monitoring, and performance reviews—is essential for mitigating these risks.

Understanding the complex balance between leveraging third-party advantages and managing associated vulnerabilities is critical when evaluating in-house vs third-party vendor strategies for sustainable business success.

For example, when considering corporate apparel as part of your branding strategy, you might explore options like embroidered polo shirts or screen-printed t-shirts, both of which can significantly enhance your corporate image. However, it's crucial to ensure that any third-party vendor you engage with adheres to stringent quality standards and aligns with your brand values.

In-House Production: The Direct Control Advantage

1. Consistent Quality Standards

In-house production allows businesses to maintain direct control over every stage of the process, ensuring standards are consistently met. Having direct oversight enables immediate quality assurance, reducing errors and enhancing product reliability. For instance, in the realm of apparel production, this means that every piece of clothing can be meticulously checked for quality before it reaches the consumer.

2. Agility and Flexibility

Controlling production internally fosters agility and quick response to issues, which third-party vendors often cannot match. This flexibility is especially beneficial when dealing with custom orders, such as custom embroidered hoodies or custom apparel in general.

3. Team Appreciation

Furthermore, in-house operations provide a unique opportunity to show appreciation to team members. A great example of this is through Production Assistant Wrap Gifts, which can include custom apparel and accessories as tokens of gratitude.

4. Market Visibility

Lastly, understanding how to maintain visibility in a competitive market is crucial. As highlighted in an article about why customers forget your brand, staying relevant and memorable to customers is essential for business success. This involves not just producing quality products but also future-proofing the supply chain to adapt to changing market demands and consumer preferences.

Quality Control: A Key Differentiator Between In-House and Third-Party Vendors

Quality control is a crucial factor that sets apart in-house production from outsourcing to third-party vendors. Here's how both approaches differ:

Benefits of In-House Teams

Companies using in-house teams enjoy several advantages:

- Stricter quality control protocols implemented at every stage of production.

- Consistent adherence to product standards, ensuring customers receive reliable and defect-free items.

- Direct accountability, enabling swift identification and resolution of quality issues without bureaucratic delays.

Challenges Faced by Third-Party Vendors

On the other hand, third-party vendors often encounter difficulties in maintaining uniform standards due to multiple handling points involved. This fragmentation introduces risks such as:

- Increased potential for inconsistent product quality.

- Lack of rigorous oversight typically found in dedicated in-house operations.

- Diffused responsibility, making it harder to pinpoint and address defects promptly.

The impact on brand reputation can be significant when product inconsistencies arise from third-party outsourcing. Customers expect reliability and consistency, values that thrive under the watchful eye of an in-house team.

For instance, when a company orders custom tumblers or birthday t-shirts from a third-party vendor, the potential for inconsistent product quality or lack of personalization can jeopardize customer satisfaction.

“The Truth About Third-Party Vendors: Why In-House Matters More Than Ever” underscores this reality—direct supervision and embedded quality assurance processes in-house foster superior control and elevate customer satisfaction by minimizing errors before products reach the market.

Moreover, the significance of quality control extends beyond just tumblers and t-shirts. For businesses looking to establish a strong brand identity through custom embroidered hoodies or embroidered hats, maintaining stringent quality standards is paramount. These products not only serve practical purposes but also act as vital components of a company's branding strategy.

Furthermore, understanding the nuances of [screen printing](https://medium.com/@imprintconnect/master-screen-printing-beginner-tips-for-burning-and-exposing-screens-63c9f53303da) can further enhance the quality control process, ensuring that every printed item meets the desired standards before reaching the customer.

Operational Efficiency: The Case for In-House Teams

Operational efficiency depends on how quickly and effectively a company can respond to challenges. In-house teams are great at making communication smoother, avoiding the extra steps often needed when working with outside vendors. This direct communication leads to quicker response times, which are crucial for keeping things running smoothly and ensuring customer satisfaction.

The Advantages of In-House Teams

- Direct control over operations: Businesses can make immediate changes without waiting for outside approvals or dealing with complicated vendor processes.

- Optimized workflows: In-house staff have a deep understanding of internal processes, allowing them to improve workflows and prevent potential bottlenecks.

- Rapid issue resolution: When problems occur, in-house teams can quickly address them on-site, minimizing downtime and stopping further delays.

The Challenges of Third-Party Vendors

On the other hand, relying on outside vendors often creates communication gaps because of distance or multiple middlemen involved. These factors can lengthen resolution times and make coordination efforts more difficult. Delays in response not only disrupt operations but can also negatively impact how customers perceive the company's reliability and professionalism.

In-house operations offer a level of flexibility that third-party partnerships find hard to match. This flexibility is crucial for businesses that want to maintain high service standards while quickly adapting to changing circumstances or unexpected disruptions.

Moreover, fostering a sense of employee pride within in-house teams can further enhance operational efficiency. When employees take pride in their work and feel a strong connection to the brand, their motivation, teamwork, and overall productivity levels increase significantly.

Additionally, it's essential for brands to ensure their visual identity resonates well with their audience. This involves undergoing what can be termed as the "fireworks test for visual impact", which essentially assesses how well a brand's visual elements stand out and connect with its audience.

Conclusion

- Transparency is crucial for maintaining brand integrity, especially when choosing between third-party vendors and in-house solutions.

- The impact of vendor choice goes beyond mere cost, shaping customer trust and long-term brand reputation.

- In-house operations provide enhanced control and accountability, underscoring the significance of 'The Truth About Third-Party Vendors: Why In-House Matters More Than Ever'.

- Highlighting the need for vendors to offer transparency regarding the actual performers behind the scenes.

- Encouraging customers to seek clear information to make informed purchasing decisions aligned with their values and business requirements.

- For businesses looking to enhance their branding through custom apparel, understanding the impact of logo size and strategic logo placement can significantly boost visibility and perception.

- Additionally, opting for embroidered polos or personalizing baseball caps can further reinforce a company's identity in the marketplace.

FAQs (Frequently Asked Questions)

What are the main risks associated with outsourcing to third-party vendors?

Outsourcing to third-party vendors can introduce risks such as security breaches, compliance failures, inconsistent product quality, operational disruptions, and lack of accountability, which may negatively impact brand reputation and customer satisfaction.

How does in-house production enhance quality control compared to third-party outsourcing?

In-house production allows businesses to maintain direct oversight over every stage of the process, ensuring stricter quality control, consistent product standards, immediate identification and resolution of issues, and greater accountability than third-party vendors typically provide.

Why is vendor transparency important when choosing between in-house and third-party options?

Transparency is crucial for maintaining brand integrity because it enables customers to know who actually performs the work behind the scenes. Clear information about vendor practices helps businesses make informed purchasing decisions aligned with their values and operational needs.

What operational advantages do in-house teams have over third-party vendors?

In-house teams streamline communication leading to faster response times, enable quick adjustments without delays caused by external parties, foster embedded knowledge that optimizes workflows, and reduce downtime by addressing problems onsite more efficiently than relying on geographically distant or layered third-party vendors.

How can outsourcing to unknown third parties affect order fulfillment and brand reputation?

Outsourcing to unknown third parties often results in inconsistent logos, late deliveries, lack of accountability, and quality issues. These consequences can damage customer trust and harm long-term brand reputation due to diminished reliability and transparency.

What benefits do third-party vendors offer despite their risks?

Third-party vendors provide benefits including cost savings, access to specialized expertise, scalability for handling fluctuating demand, and improved operational efficiency. However, these advantages must be weighed against potential risks such as reduced control and quality assurance challenges.